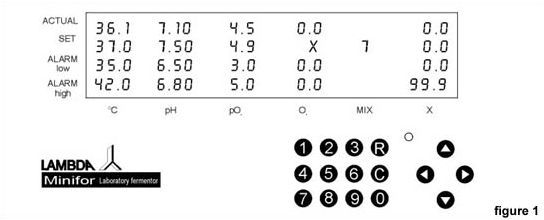

Modes:

- Standby: The Status-LED is yellow and all numbers on the display are still. This is the state of the Fermenter after switching on. The display shows the last entered parameters. In this mode all measurement readings are shown, but the regulation is switched off and the number keys blocked.

- Operation: The regulation is activated by pressing key "R" and the LED is green.

- Calibration: Key "C" starts calibration of pH, pO2, parameter X or setting of address for the PC control (depending on the choice with the cursor). The LED is yellow.

Function keys:

- "R"-Key: Switches between Standby and Operation mode (RUN, REGULATION) of the Fermenter.

- "C"-Key: Switches between Standby (no regulation, LED is yellow) and Calibration mode. During calibration this key memorizes the calibration values.

Arrow Keys:

- Pressing will activate the cursor on the display. The cursor is represented by a blinking field.

- If the cursor is already activated, pressing the arrows will move it to the corresponding direction.

- If a value is being edited (e.g. calibration value) the left arrow clears the value allowing correction, whereas the other arrows save the entered value and move the cursor to the corresponding direction.

The cursor will be deactivated automatically if no manipulation of the number keys or arrows has been effectuated during 15 seconds.

Number Keys:

Are used for setting of numerical values of parameters (if no cursor is displayed the number keys are blocked, preventing inputs by mistake).

Input modification

Place the cursor on the desired parameter. Enter the value with the number keys. The values are entered without decimal point. For example, 9.00 is entered as 900. The left arrow allows correction of the actual value, the other arrows save the entered value.

Input modification is always the same, independently of the operation mode of the Fermenter.

1.2 Probe calibration (gauging pH-probe)

- In standby mode press key "C". Move cursor on the column of the parameter to calibrate. Enter the value of the first gauging solution (e.g. pH 4.00) in the second line (SET VALUE) and press right arrow. The value is displayed in the line below. The probe can now be immersed into the gauging solution. The probe is stirred gently until the measured value (ACTUAL) is stabilised. Then key "C" is pressed again.

- The value of the second gauging solution is entered as described above and the right arrow pressed. The probe is immersed into the gauging solution, gently stirring until the measured value is stabilised. Then key "C" is pressed. An OK message is displayed if the calibration has been performed correctly. Calibration can be interrupted at any moment by pressing key "R". If the calibration is interrupted the values of the former calibration remain unchanged. (For checking purposes the probes are immersed in the gauging solutions and the correct values must be displayed.)

It is important that the sequence as described above is observed exactly! If not, the calibration has not been effectuated properly and has to be repeated.

By pressing key "R" the Fermenter switches to the Standby mode, and anew pressing of key "R" sets the Fermenter to the Operation mode.

MESSAGES

OK - calibration successful

err0 - same gauging solution used twice

err1 - same value entered twice

1.3 Setting the temperature

Move the cursor with the arrows on the field for the temperature setting (SET C, second row, first column). Enter the desired temperature (the value shown on the first line and first column corresponds to the measured temperature and cannot be changed).

Move the cursor on the field of temperature minimum (ALARM LOW). Enter the desired value. If the temperature falls below this value, an alarm is activated and at the exceeded value an asterisk is displayed.

Move the cursor on the field of temperature maximum (ALARM HIGH). Enter the desired value. If the temperature exceeds this value, an alarm is activated and the exceeded value is highlighted on the display.

>> Up

1.4 Setting of the other parameters

The remaining parameters are set analogically to the temperature.

Remarks:

- If the cursor leaves the field (arrows right, up or down) the modified value is automatically saved.

- When the alarm is activated, a continuous 12V signal is present on the alarm output. This is very helpful for directing the alarm to other places, e.g. by phone or activating a sample collection with the aid of the sample collector OMNICOLL. Such samples can contribute to clarification of alarms during unattended fermentation.

- The alarm is deactivated if key "C" is pressed in the calibration mode. The alarm is not activated if the corresponding value of ALARM LOW has been set to 0.0 or 0.00 previously. This prevents alarms of unused functions, e.g. parameter X. (For non zero values alarm is activated).

- For the mixing function (MIX) only the desired value can be entered. The actual value corresponds automatically to the desired value, because the frequency of mixing is controlled precisely through the electronics and deviation thereof is not possible.

1.5 Regulation of pO2

The concentration of dissolved oxygen (pO2) can be regulated by the airflow. This regulation is activated by entering a value for pO2 into the field of the desired pO2 value. The symbol "X" appears on the display at the location of the desired airflow to point out that the airflow is determined by the pO2. The measured airflow value is shown and corresponding alarms (ALARM HIGH, ALARM LOW) can be set. To return to the airflow regulating mode, move the cursor on the field of the airflow and enter the desired value. The symbol "X" is now displayed at the location of the set pO2.

1.6 Calibration of the probes

Calibration of the pH-probe

v. 1. Calibration (Chapter 1.2)

Calibration of the pO2-probe

v. 1. Calibration (Chapter 1.2)

For the 0%-level the gauging solution is a 5% aqueous solution of Na2SO3 (first gauging solution). For the 100%-level, oxygen-saturated water by air is used (second gauging solution).

Calibration of the X-channel

v. 1. Calibration (Chapter 1.2)

Remark:

Temperature probe, flow meter and the mixing frequency cannot be calibrated. Their actual values are guaranteed and controlled electronically.

1.7 START/STOP-Key "R"

START/STOP- or STANDBY-Key "R" activates and deactivates regulation and alarms. The measured values are not influenced thereby and the actual values are displayed. This is helpful during calibration of the probes and the preparation of the Fermenter. In standby mode the LED is yellow. In operation mode it is green.

1.8 PC-Connection

The PC is connected at the back of the Fermenter with a DB 9 connector. The different fermentation parameters can be modified from the PC. A Windows compatible program (FNet) is available. It enables data acquisition and real-time visualisation of the different parameters.

>> Up

2. PREPARATION AND STERILISATION OF THE MINIFOR

2.1 Preparation of the vessel

2.1.1 Mounting of the vibration mixer

The disassembled head is shown in figure 2.

Place the membrane 2a on the lower side of the cock head and screw the axis of the mixer on the mobile part of the cock head (figure 5).

This membrane guarantees the sterility and must be faultless and well mounted!

The mixing disc is positioned on the axis, about 1 cm from the end, and tightened by the socket head screw (figure 6). The gas distributor is screwed onto the axis with a socket head screw (figure 7).

The gassing holes can be cleaned with a wire if necessary.

The head is tightly screwed onto the Fermenter vessel with nut 8h (figure 8).

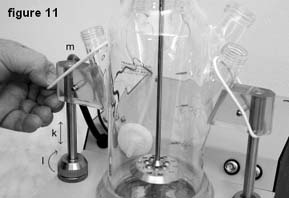

For mounting, it is advantageous to fix the Fermenter vessel onto the housing (figure 11). The lateral holders are adjusted to the right height of the vessel 11k and fixed in position by rotating ring 11l. Elastic O-rings 11m affix the side-necks to the holder.

>> Up

2.1.3 Air outflow

Silicone seal, Teflon washer and screw-hole cap are placed onto the glas air outflow cooler (figure 12).

A silicone tube is fixed onto the outflow cooler on one side and onto the corresponding filter on the other side. The air outflow cooler is now screwed into the side neck of the Fermenter vessel (figure 13).

Alternativelly an electrothermical Peltier cooler can be used. It allows a much better condensation of water vapor because of low temperature attained (about 0 °C). No cooling water is required.

2.2 Cannulae for addition and sample collection

The large silicone plug is screwed, together with a washer, to the larger side neck using the screw-hole cap Pyrex 30. If necessary Luer-Lock end pieces are mounted onto the top of the cannulae (figure 14). The long cannula is preferably used for sample collection, the shorter cannulae are used for addition of pH-adjusting substances and inoculation

2.3 Probes

The pH-, pO2- or other probes are connected correspondingly. After calibration they are provided with a silicone plug, Teflon washer and screwed onto the side necks with the aid of a screw-hole cap (figure 15).

Remarks:

Before sterilisation the vessel is filled with medium and all unused side necks are sealed with a silicon stopper, gasket and a cap. The probe connectors have also to be protected with a cap, unless they are of the VarioPin type, which does not need protection.

>> Up

3. START OF THE FERMENTATION

3.1 Connections

The cooled off Fermenter vessel is placed into the ring above the infrared heat emitter and has to be well supported by the lateral holders (figure 11). The lateral holders are fixed in position by rotating ring 11l. Elastic O-rings 11m affix the side-necks to the holder.

- Connect the compressed air of 0.1 MPa (maximum 0.2 MPa) at the connector on the backside. The sterilised air inflow tubing containing the filter is fitted on the air tube at the front on the left. The tubing is affixed by common clamps.

- The electromagnet 16n is screwed, as far as it will go, onto the axis of the cock (figure 16). The cap nut 17 is tightly screwed onto the cock head (figure 17).

- The probes are connected properly to the control unit.

- The sterilised tubing is inserted into the pump heads, the pumps placed onto the racks and connected to the control unit of the Fermenter. The tubings are connected to the supply bottles. The tubing ends are preferably passed by flame to avoid any contamination.

- The supply bottles are placed into the magnetic supports and positioned onto the housing of the Fermenter (figure 18).

- Switch on the pumps, press REMOTE key and choose the direction of rotation. They are still blocked by the microprocessor.

3.2 Start-up of the Fermenter

After a last control of the connections, press key "R". Regulation is now activated.

Once the desired parameter values are reached, inoculation can be performed.

|