- Instead of a fermenter flask with a stainless steel cover, which is expensive, we use whole glass vessels with threaded fittings. They have been used for many years in cell culture and are proved to maintain perfect sterility.

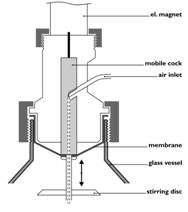

- Instead of a traditional propeller agitator, which requires an expensive motor and magnetic coupling, we have introduced a new vibration mixer. An electromagnet and an inexpensive membrane which can perfectly assure sterility and produce an efficient mixing without formation of a vortex (no baffles are needed). At the same time this type of mixing is more gentle on cells and produces less foam.

- The culture is heated by heat radiation produced in a parabolic radiator with a gold reflector placed under the fermentation vessel. The heat is adsorbed gently in the culture in a similar way to the sun heating water. There is no overheating of the culture, as is usually the case when a heater is placed in the medium and expensive double wall vessels with thermostatic baths are eliminated. At the same time pipes and cables disappear making the fermenter less complex.

- As far as possible expensive pieces of equipment have been replaced by new high performance plastics.

- By using modern microprocessors it has been possible to position all the electronics in the front part of the instrument this makes the fermenter unbelievably compact and eliminates the casing tower usual in other products. Despite its small size six parameters are measured and controlled in the basic configuration of the Minifor.

Obtained diploma for the LAMBDA MINIFOR laboratory bioreactor/fermenter during the competition “INNOVATION of the year 2007” held in Prague on 7th December 2007.

|

Technical description:

Basic unit:

The main feature of the Minifor is that all the electronics, power supply, IR heater, air valve, mass flow meter, cables and tubing are positioned in one base unit, which is used as a support for a fermentation vessel and all other necessary equipment. The platform arrangement of the base unit makes all parts of the fermenter clearly visible and easily accessible from all sides despite base dimensions of only 22 X 40 cm (approx. an A4 sheet of paper).

Up to five 250 ml reagent bottles in magnetic holders can be placed behind the fermenter vessel and up to 4 pumps can be placed on adjustable holders mounted on bars at the rear part of the base unit. The sockets are located on the rear side of the base unit thus removing cables from the work area.

|

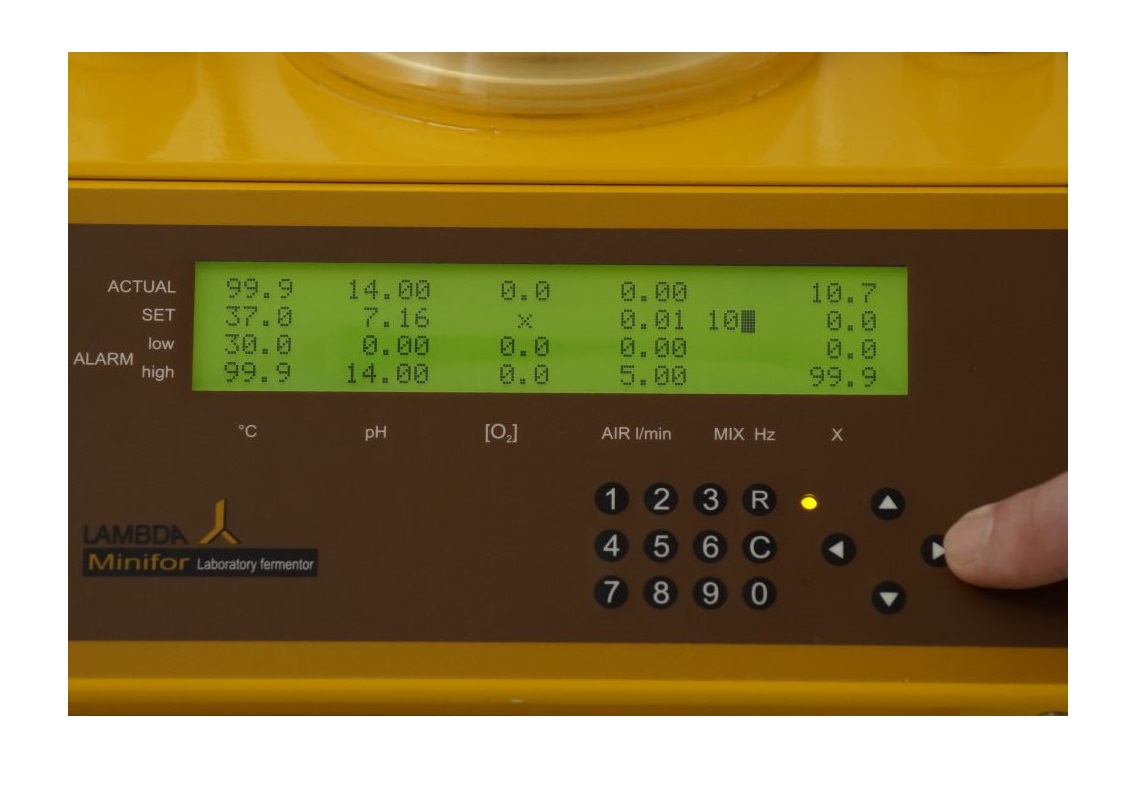

Measurement and regulation:

The control panel consists of an LCD display and control buttons. All parameters (temperature, pH, pO2, air flow rate, agitation and one free selectable parameter (for ex. pCO2, optical density, antifoam, redox potential, conductivity etc.) are visible at a glance on a large LCD back light display (4 X 40 digits). The controls are simple and logical.

On most parameters the limits of low or/and high alarm can be set. After alarm activation an acoustic signal is heard, an indication appears on the display and an electric signal appears on the rear side connector of the fermenter. Each fermenter can be operated in an autonomous way or can be coupled to a PC (over RS 485) using a special fermentation program (FNet or SIAM). This allows almost unlimited possibilities for control and data treatment (many fermenters in parallel).

|

Fermentation vessel:

The standard fermentation vessel has a total volume of 1 litre (other volumes from 35 ml to 6 l can be delivered on request). The vessels are made of high quality Pyrex glass with one large threaded central opening for the fixation of the membrane and vibromixer and 6 to 8 threaded side necks for the fixation of different sensors, air outlet, sample withdrawal, inoculation etc. Two adjustable holders hold the vessel in position. The vessel is sterilised in an autoclave.

|

| Vessel type: | 0.3 | 0.4 | 1 | 3 | 7 |

| |  |  |  |  |  |

| Volume [L]: | 0.035–0.4 | 0.15–0.45 | 0.3–1.7 | 0.5–3 | 1–6 |

↑ Up

Agitation:

Instead of a traditional propeller agitator a new vibromixer is used in the Minifor. A strong electromagnet moves one or several perforated discs up and down. The major advantage is an efficient mixing and aeration of the culture medium together with very efficient separation of the inside of the vessel from the outside by a low cost silicone membrane. No vortex is built up and baffles are eliminated. This type of agitation is also gentler on the cells and foaming is reduced. A very efficient mixing is achieved with the novel elastic “fish-tail” stirring discs. They combine maximum mixing efficiency without cutting edges - the optimal choice for cell cultures. The frequency of vibration is controlled by a microprocessor and can be varied through a broad range. The input of air is made through elastic selfcleaning microsparger fixed under the lowest disc.

|

Air input:

The flow rate can be set from 0 to 5 l/min. in 0.01 steps. A precise mass-flow meter is used. This measurement is independent of the pressure and temperature variation of the air. Commonly used floating ball capillaries give inaccurate readings in this case. A proportional air valve using memory metals adjusts the flow rate. A new self-cleaning elastic air micro-sparger has been developed. Its special construction allows an automatic elimination of salt deposits, which would block the airflow in normal spargers. This is important particularly for micro-spargers having very narrow channels.

|

Air output:

Used air is filtered by a PTFE filter. If necessary an optional Peltier condenser can be used to remove water vapour from the stream. The condenser based on a Peltier cell uses no cooling water.

|

Temperature control:

A new-patented IR radiator with a gilded parabolic reflector is used to warm the culture broth. The heat radiation (150 W) is concentrated on the bottom of the vessel where it is adsorbed by the medium in a similar way to the sun heating water. There is no overheating of the culture common with heaters placed directly in the medium. Thanks to the low heat capacity of the IR source, overshooting of the temperature is reduced and the temperature can be controlled more precisely. The temperature sensor is placed directly in the pH sensor and is used at the same time for an automatic correction of pH and pO2 electrodes.

|

pH measurement and control:

|

The pH is measured by a combined, sterilisable pH electrode with incorporated temperature sensor and automatic temperature control. Thanks to a new multiple plug Variopin it can be sterilised without any protection. The two-point calibration of the electrode is semiautomatic. The pH value has an automatic temperature correction. The addition of acid or base is controlled by a micro-processor. The flow rate of pumps Preciflow, Multiflow or HiFlow is varied between 0 to 100 %, which makes the pH control smoother than with the common ON/OFF switching of pumps with fixed speed. The unique Pump flow Integrator (option) when coupled to the pump enables monitoring of the pumps activity during the process. This yields precise kinetic data concerning the culture state and activity.

|

pO2 measurement and regulation:

A sterilisable Clark-type electrode with large cathode measures the concentration of dissolved oxygen with a glass reinforced TEFLON membrane giving fast response times. and short polarization. The major part of the membrane is protected against mechanical injury by a thin wall of PEEK. The microprocessor performs a semiautomatic two-point calibration with automatic temperature control. The regulation of dissolved oxygen is obtained by a variation of the flow rate of air.

|

↑ Up

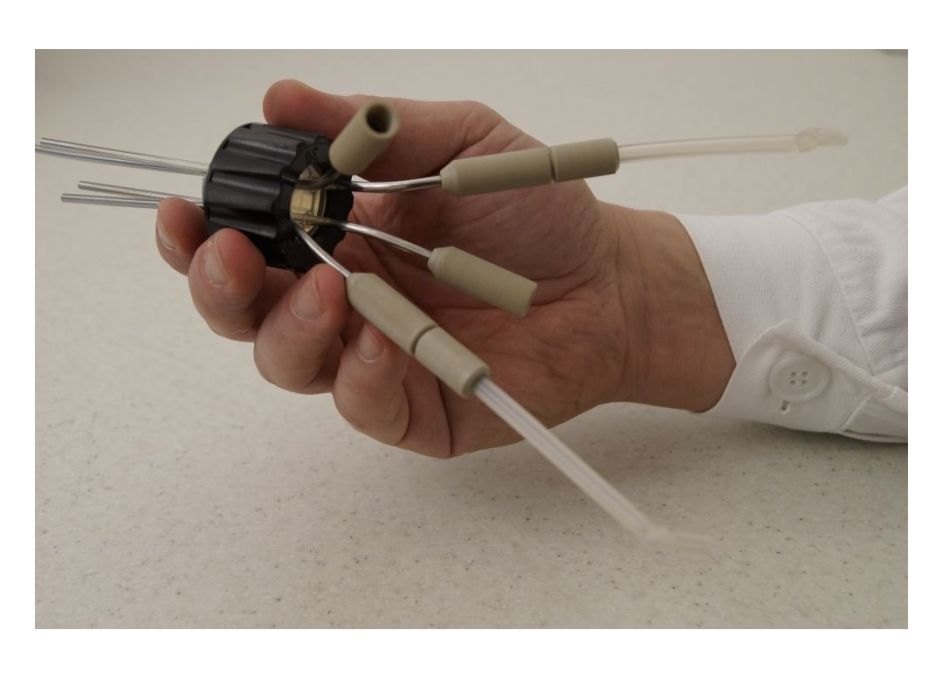

Inoculation and sampling ports:

Inoculation, addition of acid or base and sample removal is made through four stainless steel capillaries equipped with Luer-Lock adapters or multiseal PEEK connectors.

|

Sterilisation:

The fermentation vessel is sterilized as usual in an autoclave after disconnection of the cables from the electrodes and vibromixer.

Dimensions:

A lot of effort was made to make the Minifor as small and as compact as possible. The platform arrangement of the fermenter makes control and access to all parts easy from all sides.The distance between the reagent bottles, pumps placed above them and the fermenter vessel is the shortest possible.

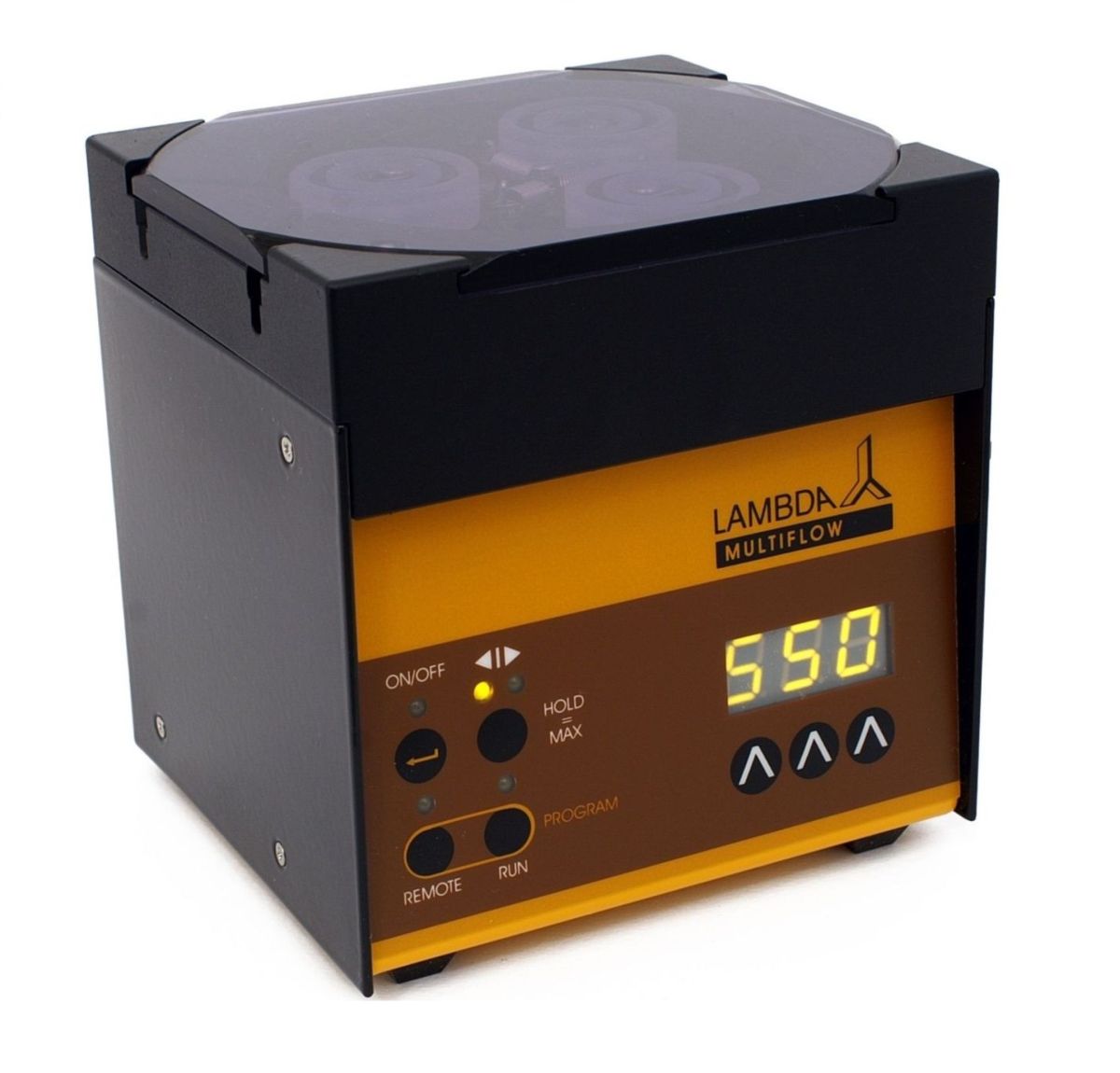

Peristaltic Pumps:

Up to four peristaltic pumps Preciflow, Multiflow or HiFlow can be placed on holders fixed on two bars at the rear of the fermenter. They are connected by a single cable to the sockets on the rear side of the fermenter. Since the peristaltic pumps are not bound to the fermenter they can be used for other applications elsewhere in the laboratory (for ex. for chromatography etc.). This can present a considerable economy for the user.

|

|

PC software:

FNet was specially developed for the monitoring and control of fermentation processes and cell cultures with the LAMBDA MINIFOR fermentor. The software runs under Windows NT, 2000, XP, Vista and Windows 7 and 8:

|

SIAM is a high quality industrial and laboratory software for professionals with almost unlimited possibilities for up to 99 fermentors and extended functions. It is user friendly and economic (low price and reduced learn phase). Developed specially for research laboratories, but it is also a tool for pilot plants and small production units. The user can build their own application within a few minutes.

MINI-4-gas automatic Gas-Mixing module software

The LAMBDA gas-mixing module allows a flexible mass flow controlled supply of different gasses with their individual gas flow paths. The gassing system automatically mixes up to four gasses for the cell culture system. The automatically controlled aeration system provides advanced gas diffusion by sparging and / or headspace gassing. The extension of the SIAM software allows a complete automatic gas-mix control for up to 4 MINIFOR parallel-reactors (4 x 4 gas flow controller).

Types of Gas-Mix systems:

- 4-gas-mix for stem cell & mammalian cell culturing

- 3-gas-mix for anaerobe fermentation

- O2-enrichment for microbial systems & biofuel development

↑ Up

|